DRIFT EP8: MP Rezeau machines the cylinder heads for our B58s and assembles them at Pepinox

Today, we start the 8th episode of our drift car project and take you to MP-Rezeau, a specialist in car preparation, and more specifically Alpine A110s. Here, we don't just fit existing parts: we make them to measure to get the best out of them.

Based in Argent-sur-Sauldre, this company masters every stage, from 3D scanning of the parts to their machining using ultra-precise 5-axis CNC machines. The aim? To optimise every component to improve engine performance and reliability.

In this article, we'll be following each stage: the study of the original cylinder heads and their 3D scan, machining and assembly. Let's get down to the nitty-gritty of precision engineering!

Who is MP-Rezeau?

MP-Rezeau, founded by Yannick Rezeau, is much more than just a car preparation workshop. Specialising in Alpine A110s, the company not only modifies existing parts, but also designs and manufactures them itself. Thanks to its expertise, it can offer tailor-made solutions to improve the performance and reliability of these sports cars.

Our unique expertise is organised into four areas:

- Automotive Workshop: MP-Rezeau restores and prepares classic and sports cars, with the emphasis on precision and performance.

- Precision Machining: Equipped with ultra-high-performance machines, the company manufactures its own parts in aluminium, steel or titanium to an exceptional level of finish.

- Research and Development (R&D): Developing advanced mechanical solutions, creating test benches and designing special parts for demanding projects.

- Retrofit : An innovative approach that consists of converting internal combustion vehicles into electric vehicles while preserving their original DNA.

This versatility enables MP-Rezeau to meet the needs of Alpine A110 enthusiasts, but not only that, as they will also take care of our BMW cylinder heads.

3D scanning: The first step in the machining process

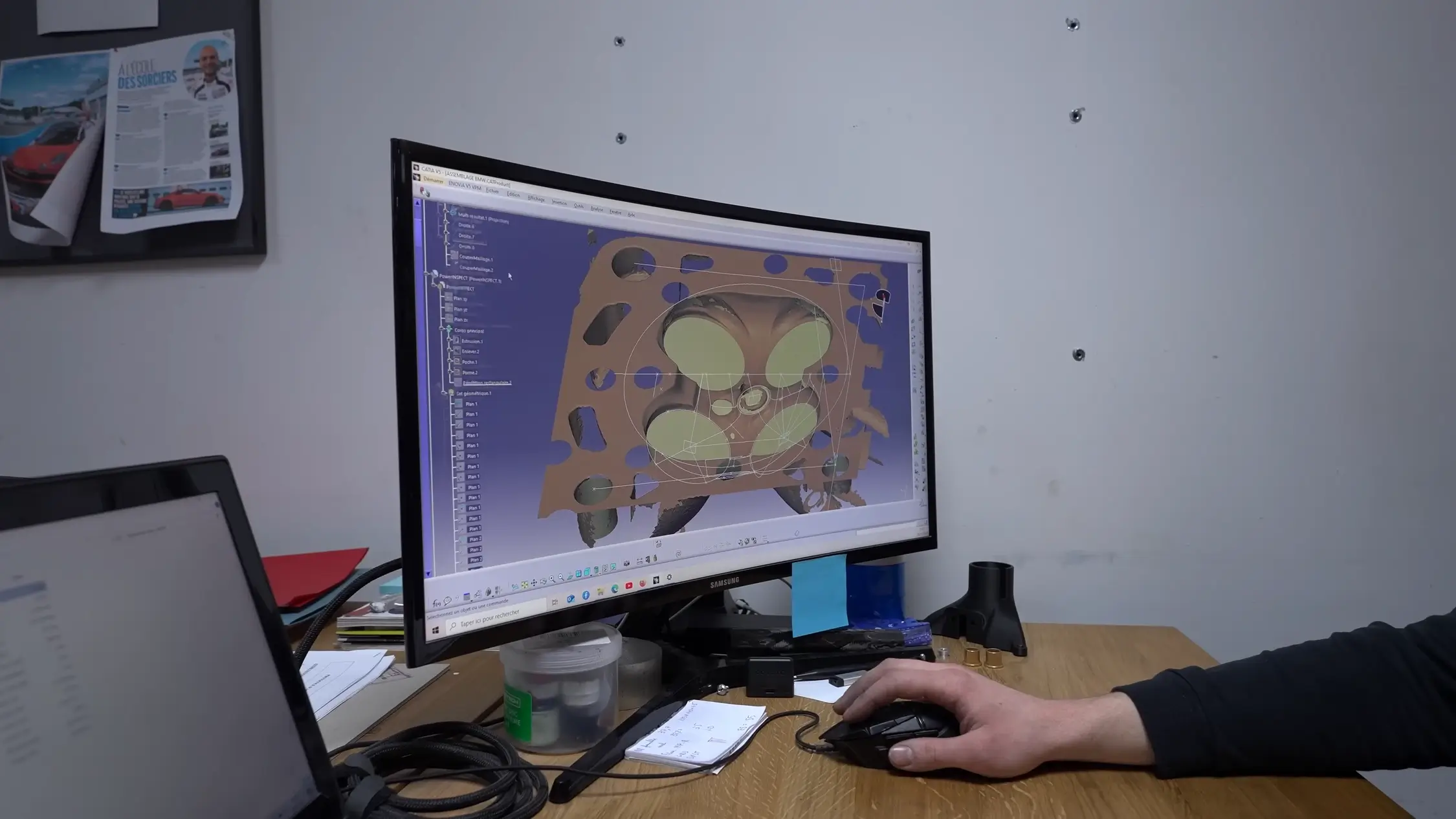

Before machining a part, it must first be analysed in minute detail. That's where 3D scanning comes in, a technology that can reproduce an ultra-precise digital model of the original part. In our case, it's a BMW B58 cylinder head, which will then be modified to improve its performance.

We meet Lucas, MP-Rezeau's 3D scan expert. On his screen, we see a multitude of small dots that gradually form a virtual model of the cylinder head. The aim is to recreate a faithful image that can be used for further machining. Using a probe, it then adjusts certain details to ensure maximum precision.

Once the scan is complete, it's time for the modelling. Lucas superimposes the digital image on the original part to check for the slightest deviation. Every tenth of a millimetre counts here, because the slightest inaccuracy could compromise the final performance.

This stage is essential: it allows us to prepare a perfect plan for machining and to anticipate any adjustments that need to be made. Now that the model is ready, it's time to move on to the next stage: programming the 5-axis CNC!

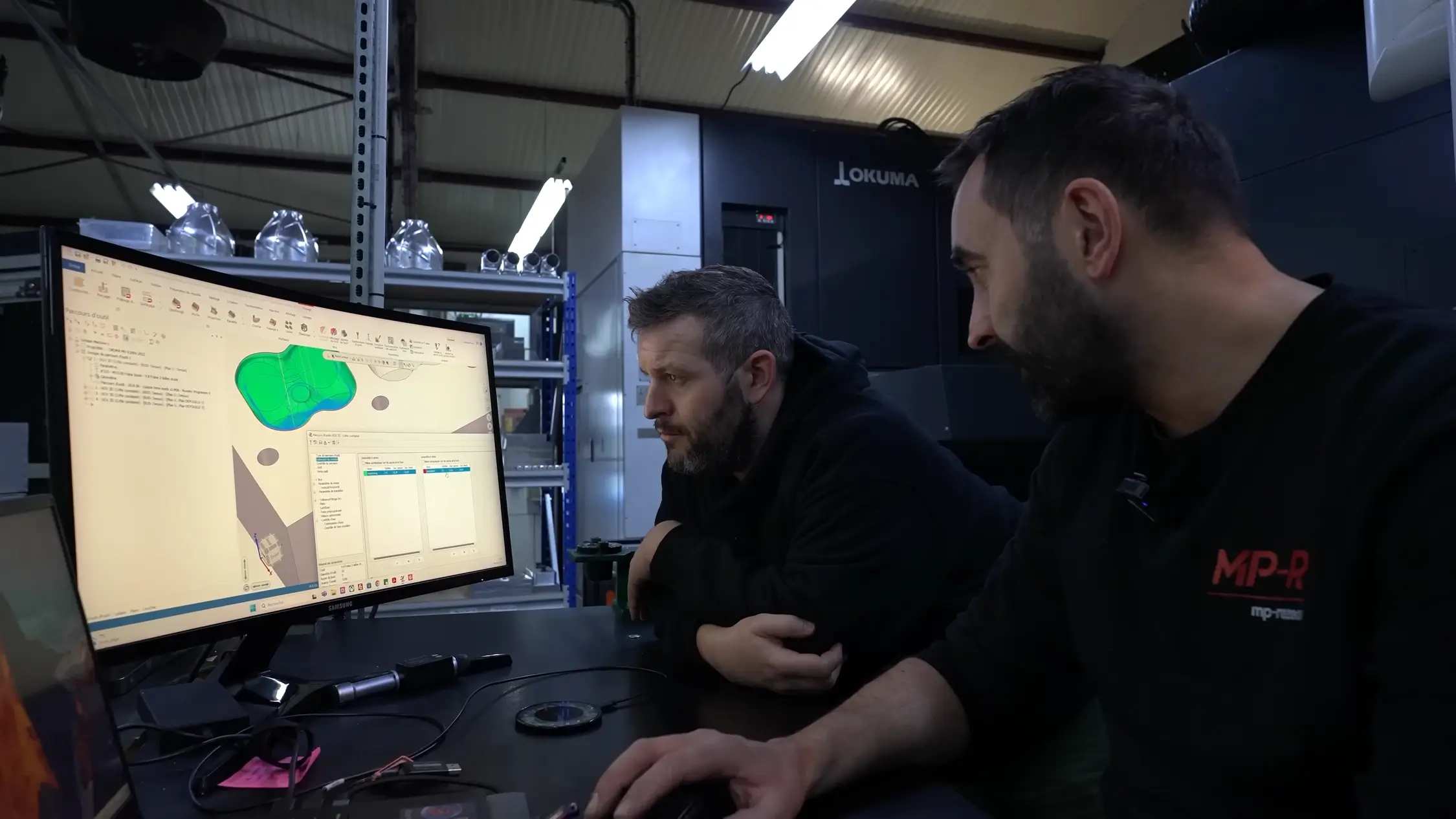

Machining programming: Big machinery

The 3D scan provided a precise model of the cylinder head, but before the machine tool could machine it, it had to go through the programming stage. This is where Yannick comes in.

using the digital model, they define each path that the machining tool will follow. This includes several parameters: depth of cut, machining speed, angles of attack... Nothing is left to chance. Contrary to what you might think, it's not enough to launch the machine with a simple click. Machining is a meticulous process that requires a great deal of thought beforehand.

One of the crucial points at this stage is to optimise machining so that it is as efficient as possible while preserving the material. Removing too much could weaken the part, while machining too lightly may not be enough to achieve the expected performance.

Once the programming has been finalised, a simulation test is carried out. This allows us to check that the trajectories are optimal and that there is no risk of error before moving on to real production. Once everything has been validated, it's time to start machining and transform the model into a part ready to be fitted to the engine.

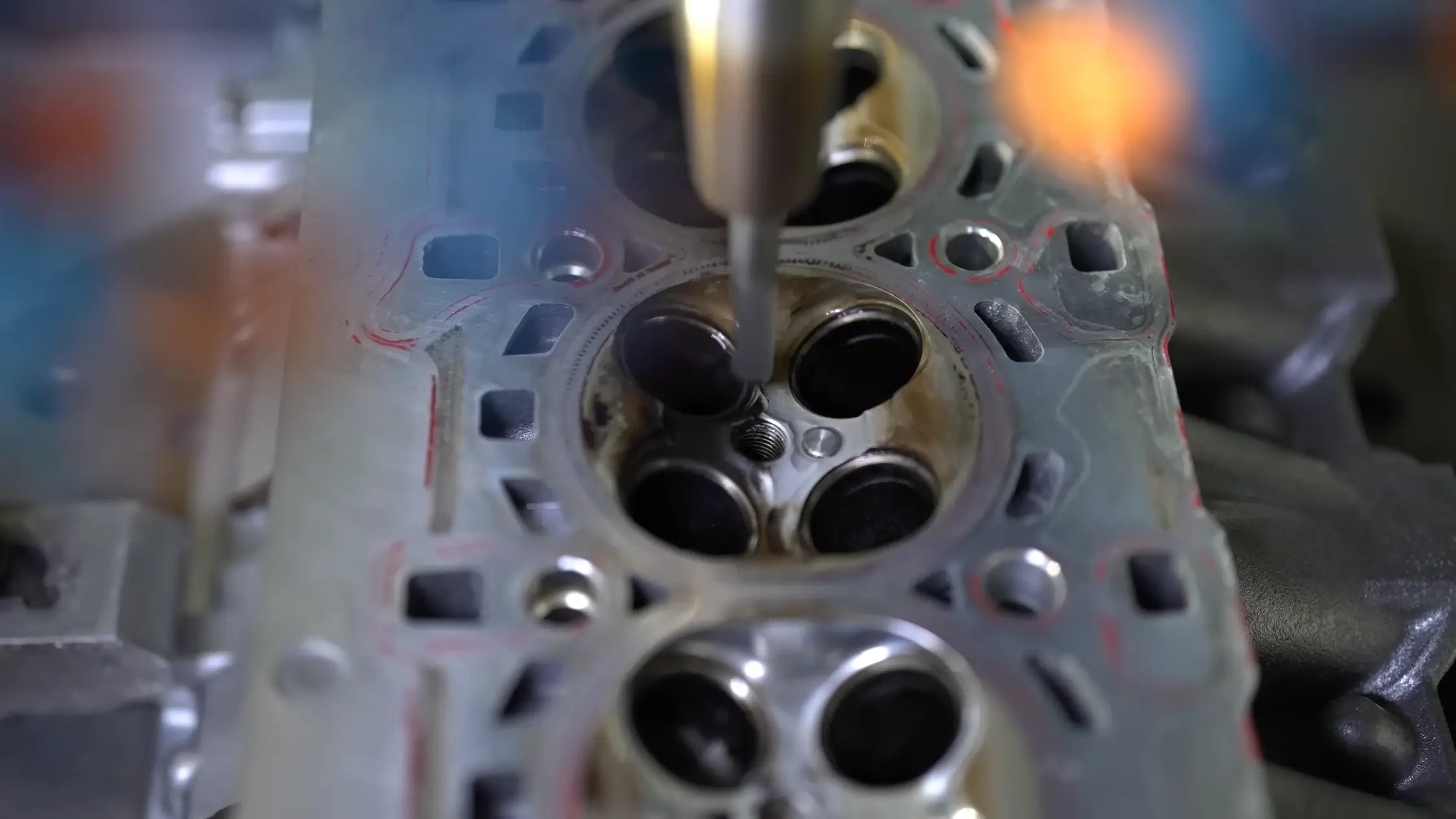

Machining engine parts: The machine goes into action

Everything is ready, all that remains is to start the machine and observe the work. Machining is carried out on a 5-axis CNC milling machine, a machine capable of working the part from several angles without the need for manual repositioning. This is what makes it possible to achieve such a precise result.

The yoke is firmly fixed to the machine table. Before starting, a final check is made to ensure that it is perfectly aligned. Then the cutter starts moving, removing tiny layers of metal with each pass. The characteristic sound of cutting echoes through the workshop, while cutting oil is sprayed continuously to cool the tool and prevent overheating.

Each step is closely monitored. A minor error in programming or poor positioning could ruin the part. Here, everything is under control: the machine executes commands with impressive precision. The process takes several hours, the time needed to guarantee impeccable work.

Once machining is complete, the cylinder head is removed and meticulously inspected. Dimensions are checked with metrology tools to ensure that they correspond exactly to the established drawings. The part is then cleaned and ready to be fitted to the engine.

Presentation of engine components: Optimised configuration

After machining the cylinder heads, we turn our attention to the various parts that make up the engine. With Ted, we go through each essential element to understand their role and the reasons for their selection.

The first key element is the weight of the engine. Depending on the choice of materials and the modifications made, the engine can be made lighter and perform better. The aim is to reduce the moving mass while maintaining optimum strength.

Here are the main parts used in our configuration:

- Boostline connecting rods: more resistant, they are designed to take heavy loads and avoid any deformation at high revs.

- Carillo pistons: forged and lightened, they provide better revs and improved thermal efficiency.

- Ferrea valves: adapted to high temperatures and high pressures to optimise engine filling.

- GSC camshafts: improve valve opening and lift to maximise intake and exhaust.

- Titanium cotters and reinforced springs: ensure good valve retention and prevent valve float at high engine speeds.

- ATI pulley: reduces crankshaft vibration and improves the longevity of internal components.

- Wagner intake pipe: improves air flow and optimises combustion.

- ARP 625 bolts and nuts: guarantee precise, strong tightening on critical components.

During the discussion, Ted explains how each part has been chosen to adapt to the engine's constraints and improve its performance. The idea is to obtain a coherent whole where each element plays a precise role in optimising the engine.

Pépinox drift and rally specialist

Based in Jonquières, Pépinox specialises in car preparation and the manufacture of custom exhausts. Known for its expertise in engine performance, it offers solutions tailored to the needs of drift, circuit and rally enthusiasts.

The workshop designs and manufactures fully customised exhaust systems, optimising gas flow and engine performance. But Pépinox is also an expert in mechanical preparation and adaptation of parts for competition.

Thanks to its artisanal approach and uncompromising quality standards, the company has become a benchmark for those looking to get the best out of their vehicle, whether it's for enhanced performance on the track or meticulous work on one-off projects.

See you soon in the next part of the project, the assembly of the block!

Our Youtube video

Learn more

View articles

Similar